High tech solutions for use over and under water

We are a developer and manufacturer of high tech solutions for use over and under water within the segments:

With an extensive catalogue, we offer a diverse range of products tailored to these markets. Additionally, our dedicated teams excel in delivering customised special solutions to meet your specific needs.

We have developed key capabilities in 5 major areas over 30 years in industry. These are:

With a specific emphasis on plastics moulding and integrated electronics within the marine environment, we offer distinct advantages to our customers through our ability to combine these capabilities. This unique synergy provides exceptional opportunities and value to our clients.

As an industry leader, we have a global presence and a deep understanding of your high expectations for quality, design and technology.

Our goal is to not only meet, but exceed these expectations by leveraging our extensive experience and fostering a culture of innovation.

With our distinctive expertise in plastics, moulding, and electronics, we deliver unmatched value across diverse industries, offering solutions that go beyond what others can provide.

Our vision is to transform areas over and under water into a safe, profitable and sustainable workplace. That's why we recycle our plastic products, and actively work towards a more sustainable product range.

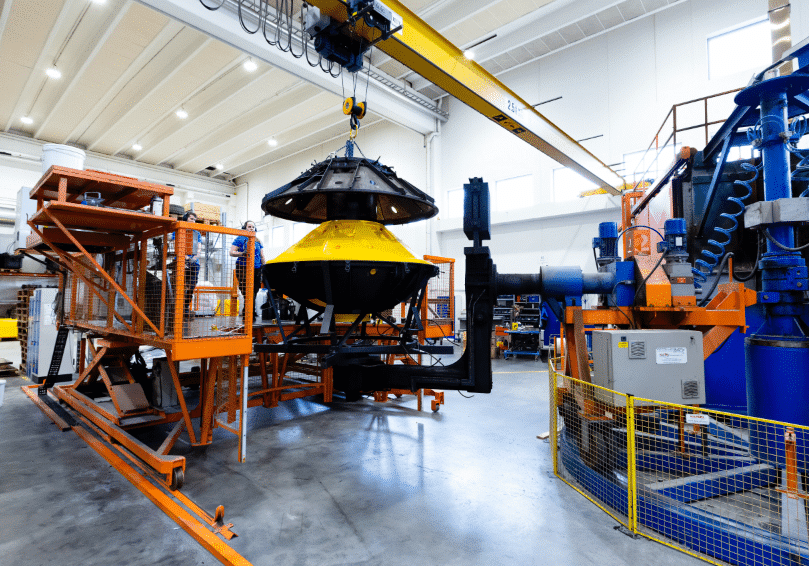

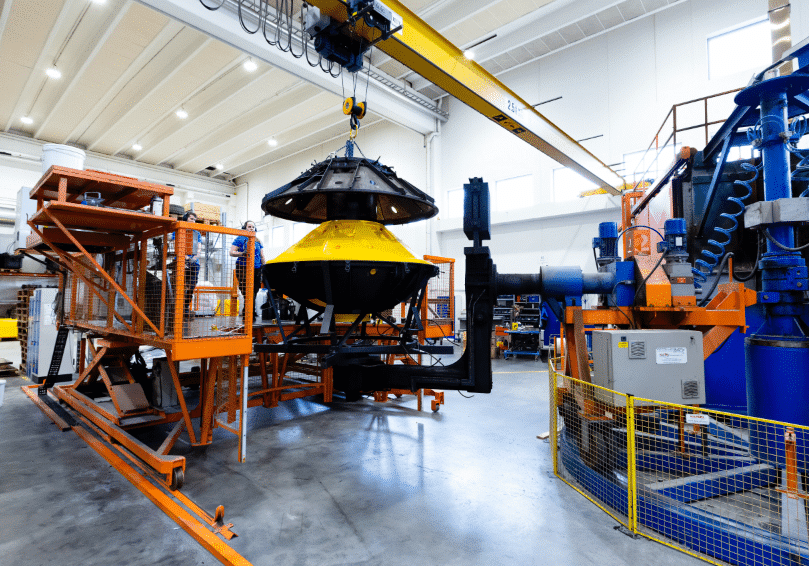

Ovun has been supplying PGS with buoy and float solutions for over 20 years

Client: PGS

When: September 2023

Asset Supervisor in Operations in PGS, Bradley Bertsch, writes this about the collaboration with Ovun, and the products we have delivered for them: “Ovun has been supplying PGS with buoy and float solutions for over 20 years. Their products have proven to be very reliable and withstand the test of time in the harsh seismic environment where they are in operation. The seismic industry has unique requirements and PGS operations set the benchmark for quality and innovation, so much of the equipment PGS utilizes from Ovun has been specially designed, including floats, winch systems, positioning systems, power supplies, generators, lights as well as onboard control and monitoring systems. Ovun works closely with PGS to successfully develop innovative solutions to meet a constantly evolving market and assist in maintaining and servicing the vast amount of equipment currently in use. The quality of equipment supplied to PGS for use in daily operations has been great, lasting well beyond expectations. An array of floats is used to monitor position, control depth and placement of many thousands of meters of towed cables. The floats are equipped with signal lights, power system and batteries, generators, winches, radios, solar panels and are integrated with PGS positioning and acoustic systems.”